|

| 7 QC Tools and SPC Training @ Roca, Parryware 19-11-2015 |

It was a great experience for me to deliver "7QC Tools & SPC training" at company site Roca, Parryware, Alwar Rajasthan

|

| 7 QC Tools and SPC Training @ Roca, Parryware 20-11-2015 |

Roca is a Spanish company and an international brand, manufacturing different kinds of bathroom products across the world.

Company is deeply concerned about the quality delivered in their product, hence organized the training program for two days at its manufacturing site Alwar, Rajasthan.

|

| Mr. Narender Sharma with Mr. Avadhesh K Mishra |

|

| Mr. Narender Sharma with Avadhesh K Mishra |

The Company intended to aware its staff regarding the 7 quality control tools and SPC, so that they can collect, and analyse the data to make continuous improvement in their respective work process.

The participants were from management, engineering, executive level and almost from every department so that quality can better be spread out in the daily life of the company culture.

The 7 Quality Control tools are highly effective in understanding current process, data collection, data presentation, data analysis, and control the process with use of statistical process control (SPC) technique.

I would like to pay my thanks to Mr.Francesc Recasens Brianso - Manufacturing Manager, and Mr. Ajay Sharma, Sr. Manager training and development, Roca, having chosen me for this opportunity.

I would like to pay my thanks to Mr. Avadhesh K Mishra-General Manager, Operations, Roca, for his gracious presence in the training .

|

| Mr. Narender Sharma with Mr. Narayan Prasad |

Training was organized for two days 19th and 20th Nov. 2015.

Training started with speech of Mr. Avadhesh Mishra, regarding the importance of 7 QC Tools and SPC to the participants.

Then Mr. Prasad reminded all participants about the quality policy of the company and introduced me to all participants.

After this I had taken the charge to start the training. All participants were grouped into teams and suggested to choose a name for their team. First of all, I had given some questions to all participants for pre-assessment. Then I started with first module of training.

- Mathematical definition of quality.

- SIPOC

- Process flow chart

- Check sheet

- Histogram

- Pareto diagram

- Cause and effect diagram

- Scatter chart

- Control Chart ( Mean chart, Range chart, P-chart, C-chart)

A 5 Min. practice exercise was given to every team after every tool.

Module II: Statistical Process Control

- What are the causes of variations?

- Basic concepts of SPC

- Concept of normal curve

- Process capability analysis Cp and Cpk

Module III: Case Study

After lunch a case study was discussed to better understand the use of 7QC Tools and SPC for analysing and solving the real life problem like;- Define the problem

- Business impact of the problem

- Data collection and measurement

- Analysis of data

- Root cause finding and improvement

- Control and sustain the improvement

Module IV:

Excel templates were installed to all available laptops, then all participants were trained to use and analysis of templates one by one

|

| Mr. Narender Sharma while delivering training |

- Construction and analysis of Process flow chart

- Construction and analysis of Check sheet

- Construction and analysis of Histogram

- Construction and analysis of Pareto chart

- Construction and analysis of Cause and effect diagram

- Construction and analysis of Scatter chart

- Construction and analysis of Control chart

- Process capability Cp and Cpk analysis template

Quiz

At the end of the day a quiz was organized to check the learning evaluation. The quiz was enjoyed by all participants.Closing Remark

All participants deserve appreciation for their learning attitude and practising the course work responsibly and carefully.

Suggestions and Recommendations

- Small projects should be started for continuous improvement using 7 QC tools and SPC in every department.

- Departmental team needs to be created

- The projects should be selected in concern with department head and considering the improvement opportunity

- Trainer should be called at regular interval for consulting, data analysis, project report preparation, and motivating the team-mates for goal achievements.

- Projects should be presented by its team after its successful completion to motivate others

- Success of the project should be celebrated by the department along with rest of the company.

Report by

Narender Sharma

Training Facilitator

Call: 09468267324, 08684861131

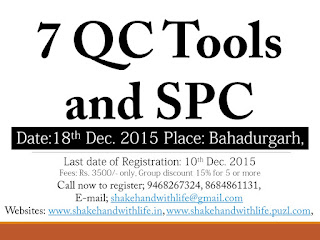

Upcoming open house "7 QC Tools and SPC" training seminar

Date: 18th Dec. 2015, Place: Bahadurgarh, for registration, training schedule and more details, click here

1 comment:

Final Year Projects for CSE

JavaScript Training in Chennai

Project Centers in Chennai For CSE

JavaScript Training in Chennai

Post a Comment