For every organization, customer satisfaction is the primary focus, so to achieve customer satisfaction it is mandatory for an organization to capture the voice of the customer clearly and so identifies the resources to manufacture a product in which the voice of the customer could be clearly reflected. But to capture the voice of the customer and then translate it into the product is quite difficult if not impossible. So if the requirements of the customer are not captured clearly then an organization never be able to produce a product according to the expectations of the customer. Here the Quality Function Deployment plays a vital role in the process of translating the customer requirements into the final product.

Quality Functional Deployment

Quality Function Deployment is a planning tool to fulfill customer expectations through product design, engineering changes, and production process. QFD is really an effective quality tool that translates the voice of the customer into the final product.

QFD first initiated by Dr. Mizuno, who was a professor at the Tokyo Institute of Technology, Japan, and the first application of QFD was in 1972 at Mitsubishi Heavy Industries, Ltd. in the Kobe Shipyard Japan.

QFD supports an organization to improve the engineering knowledge of the employees, productivity, and quality of the product and service and reduce the production costs, product development time, and engineering changes.

House🏠 of Quality

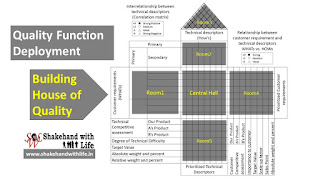

The house of quality is a significant part of the quality function deployment. An organization builds the structure of the house of quality for new product development. The house of quality has different sections/rooms for different objectives concerning customer requirements and technical requirements.

Customer Requirements: Room1

This section is like the entrance of the house and assigned for the customer requirements or the voice of the customer also known as WHATs categorizes the customer requirements into primary and secondary level.

Technical Descriptors: Room2

This section is on the first floor of the house and assigned for the technical descriptors or the voice of the organization also known as HOWs categorizes the technical requirements into primary and secondary level.

Relationship Matrix: Central Hall

In this section which is considered the central hall of the house, the QFD team studies the relationship between customer requirements and technical requirements like how closely the customer requirements are related to the technical requirements (WHATs vs HOWs)

Interrelationship Matrix: Room3

This section is on the top of the house, here the QFD team studies the interrelationship between technical descriptors like how the material of the product affects the process of manufacturing of a product (HOWs vs HOWs)

Customer Competitive Assessment and Prioritized Customer Requirements: Room4

This section is the backyard of the house, here the QFD team calculates the customer competitiveness of our product in the market compared to the competitor's product and also prioritizes the customer requirements on the basis of absolute weight and percent score.

Technical Competitive Assessment and Prioritised Technical Descriptors: Room5

This section is at the bottom of the house, here the QFD team calculates the technical competitiveness of the product and the higher ranking of the product shows the engineering superiority of the product compared to the competitors' product and also prioritizes the technical descriptors.

Aspects of Quality Function Deployment

Quality Function Deployment has two aspects 1. Quality Deployment, 2. Function Deployment

Quality Deployment

Quality deployment means translating customer requirements into product design requirements, it is a creative approach for example; the realization of the customer expectations into the design of the mobile device such as reasonable cost, nice finish, durability, feather touch, fine grip, lightweight, medium size, user friendly, etc.

Function Deployment

Function deployment means translating the product design requirements into product, parts, and process requirements, it is an action approach for example; realization of a mobile device as per design of the mobile device, planning for material procurement to manufacture the mobile device, developments of the parts like Cabinet of mobile device, PCB, ICs, Camera, Screen, Softwares, Wifi, Bluetooth, etc. Planning of the process of assembling the parts of the mobile device such as soldering, surface mounting, embedded system, etc.

Evolution of Quality Function Deployment

- 1977: The evolution of QFD started with the implementation of QFD at Toyota manufacturing with the production of Mini-Vans

- Oct. 1979: Toyota reported a 20% reduction in start-up costs in the launch of a new Van.

- Nov. 1982: Toyota reported a 38% reduction in start-up costs.

- April 1984: Toyota reported a cumulative 61% reduction in start-up costs

- 1984: QFD introduced to the United States of America in Xerox Inc. by Dr. Clausing

The Need of QFD for an Organization

QFD helps an organization in many ways and become the need of the hour as mentioned below

- Protects the voice of the customer and ensures that the voice of the customer is being heard.

- Identifies the conflicting requirements like increasing the resolution of the camera of a mobile device without increasing the cost of the mobile device and ensures that the conflicting requirements are resolved before the production

- Controls the voice of the organization to enter into the product design adversely it implies, the organization always takes care of the customer requirements and never change the design of the product on its own without taking the consent of the customer to invite the customer dissatisfaction.

- Directs the QFD team to design the product as expected by the customer

- Focuses on the need of the customer and hence avoids the improvements that customer doesn't want.

- Guarantees to implement the voice of the customer into the final product or service.

- Saves the time to design or redesign and modification of the product by one-third to one-half of the time taken by traditional means.

- Reduces the development costs.

- Saving the time to design a new product can help an organization to push the product into the market earlier than expected.

QFD Teams

QFD teams are of two types; 1. The New Product Design Team, 2. Existing Product Modification Team

The New Product Design Team

- Translates the customer requirements into new product design for example design of a new smartphone as per the customer requirements.

- Members of the team are from Marketing, Design, Quality, Finance, and Production.

- Members of the team might be from the customer side to provide the inputs for customer requirements

- Members of the team might be from the supplier side to provide the inputs for the design requirements and product planning.

The Existing Product Modification Team

- This team identifies the modification opportunities in the product through the assessment of the market performance of the product.

- For example; modification of the camera resolution and processor up-gradation of a mobile device.

- Fewer members are required in this team because of modification work only

1 comment:

Thank you for sharing your article. It was really great.

For Related more Blog Here:

mens leather corsets

mens leather corsets

Post a Comment